In an age of activist consumerism and investment, and the apparent effects of climate change, moving towards net zero emissions is the stated goal of many businesses. The questions is how do we evolve it from slogan to reality? The following is taken from “Net Zero or Bust: Beating the Abatement Cost Curve for Growth”. This article was written collaboratively by global leaders in the McKinsey Sustainability and Manufacturing & Supply Chain Practices, including Pauline Blum, Stefan Helmcke, Ruth Heuss, Thomas Hundertmark, Sebastien Marlier, Dickon Pinner, and Ken Somers.

Companies can both decarbonise and boost long-term growth, but it means pushing beyond abatement curves’ focus on cost and instead empowering people, while making a few big, strategic bets.

Before the COVID-19 pandemic, environmental, social, and governance (ESG) issues had become priority concerns for governments, businesses, investors, and consumers. As the world looks forward to the post-pandemic next normal, these themes are likely to return to the top of executives’ agendas. Among them, the need to eliminate emissions of greenhouse gases may be the most difficult to address. Many companies have already committed themselves to deep, long-term reductions in greenhouse-gas emissions. Others will be forced to act by customers, investors, and governments. Almost 300 large companies have joined the highest tier of the Science Based Targets initiative, for example — that is, ramping up pressure on suppliers to cut their own emissions or risk losing business. Business leaders are already telling us that some of their biggest customers are warning that future contracts will be contingent on significant emissions reductions.

A growing share of investment capital is also being channeled into the fight against climate change. Between 2012 and 2018, investment in assets with explicit sustainability goals grew by 15% a year. By 2018, such investments accounted for 11% of professionally managed assets globally. More broadly, investors are increasingly concerned about the potential impact of climate-related risks across their portfolios. In January 2021, BlackRock, the largest asset manager in the world, asked the CEOs of companies in which it holds shares to explain how they plan to achieve net-zero emissions by 2050.

And policy makers are piling on further pressure. The European Union, for example, appears ready to proceed with plans for a cross-border carbon tax, using the proceeds to fund sustainability initiatives within the bloc. Such policies mean companies are no longer shielded from environmental legislation by virtue of their location. Any organisation participating in global supply chains will need to cut its emissions.

Together, these forces mean that decarbonisation is no longer an option. Across most of the world, companies with ambitions to stay in business over the long term are already on a 30- or 40-year journey to net-zero emissions.

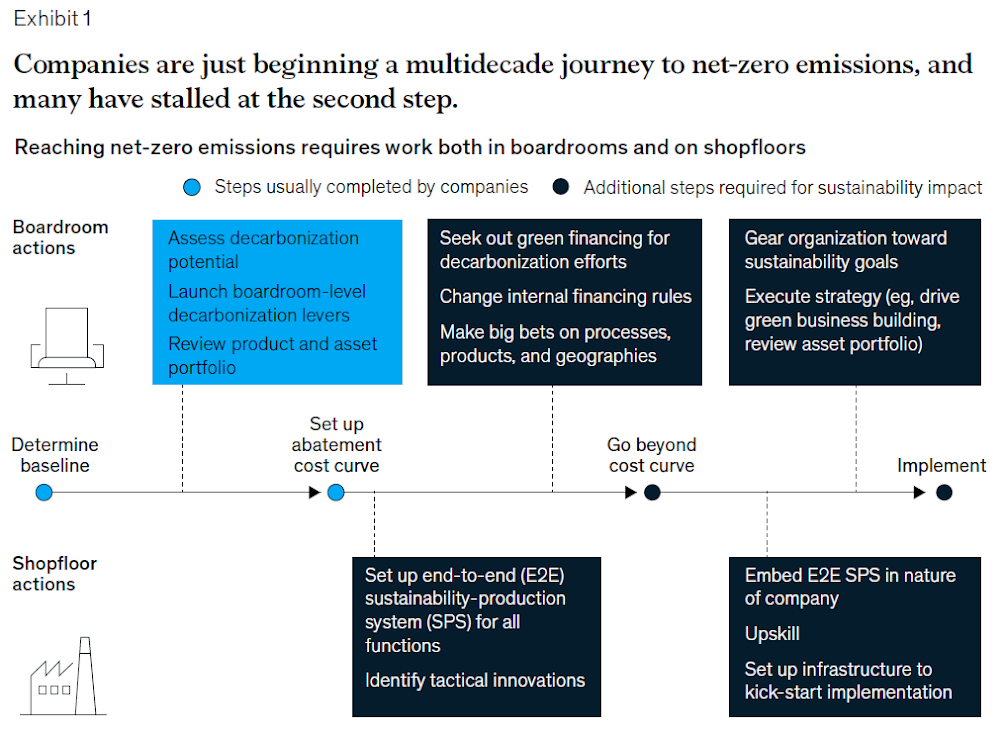

Like any change journey, the road to net zero involves several distinct steps. Companies must understand their current carbon footprints, identify strategies to reduce and ultimately eliminate carbon emissions, and implement the necessary changes.

These steps would be straightforward, were it not for one catch. Emission-reduction plans tend to be created using standard “abatement curves,” which take a top-down view and focus on large-scale technological shifts. These curves often predict that transition risks, such as falling demand or asset devaluation or regulatory shifts, will lead to cost increases great enough to put many organisations out of business long before they reach their net-zero goals.

In our view, organisations should not let the scale of the challenge derail their sustainability ambitions. Contrary to what cost curves suggest, big cuts in emissions can be achieved without large-scale value destruction. What is more, the climate transition will create historic opportunities for environmentally sustainable businesses to build new markets, reinvent old categories, and become magnets for top talent. Unilever, for example, says that in 2018, its Sustainable Living brands grew 69% faster than the rest of its portfolio. And by 2030, the reuse and recycling of plastics could drive profit-pool growth of US$60 billion for the chemicals industry, according to McKinsey analysis.

For the journey to become value creating rather than value destroying, however, companies will need to rethink the conventional approach to carbon reduction. Moving beyond the abatement curve involves a combination of top-down and bottom-up activities: empowering frontline personnel to drive emissions reductions while making significant long-term strategic bets on markets, technologies, and production footprint (Exhibit 1).

Even the first step in the carbon-reduction journey — determining baseline emissions — presents significant complexities. An organisation can use internal data sources, such as energy bills and procurement records, to calculate its emissions in the Greenhouse Gas Protocol’s Scope 1 (direct emissions from its own activities) and Scope 2 (indirect emissions attributable to the organisation’s energy use). Scope 3 emissions are more difficult to ascertain. The necessary data are not always available from suppliers and customers, forcing companies to rely on models or approximations to build an estimate of their full carbon footprint.

Even a less-than-perfect picture of emissions could still act as a useful catalyst for improvement. Understanding the largest sources of greenhouse gas emissions across value chains can help companies identify quick wins and target energy efficiency improvement efforts. Few organisations make that link, however. Emissions analyses remain locked in the boardroom, while any improvements made by the front line are simply a byproduct of efforts to reduce waste and drive up productivity using well-established lean approaches.

To establish a potential pathway to net zero, companies must identify the changes that could eliminate emissions from their value chains, then rank them in ascending order of cost per ton of abated carbon. Today, it is common to map these changes in the form of abatement curves, which provide the boardroom with a top-down view of the potential capital investments (often large) in known technologies that could trim organisation’s emissions.

For business leaders, these abatement curves can be frightening, especially for industrial companies with energy-intensive processes. Exhibit 2 shows an illustrative carbon-abatement cost curve for the full value chain of a European automotive player.

The x-axis of the chart sets out, in ascending order of cost, the available options for reducing the organisation’s carbon emissions. The y-axis shows today’s cost of each option per ton of carbon emissions reduced. At current costs, less than 25% of the path to zero emissions is positive net present value (NPV).

For this company, the chart’s implications are stark. Eliminating the company’s upstream emissions would reduce its profits by around €1 billion. At many organisations, the implications of the carbon-abatement curve have been daunting enough to stall progress on the deep emissions reductions that will be necessary over the coming decades. The imperative for today’s leaders is to find ways to break this deadlock.

Beating the cost curve and building a successful long-term decarbonisation strategy will depend on big moves in two areas (Exhibit 3). The first operationalises emission-reduction efforts using known technologies and approaches, moving from theoretical discussion in the boardroom to pragmatic action in the control room, on the shopfloor, and throughout the organisation. The second entails big bets on options that don’t currently appear on the abatement curve, exploring new technical, strategic, and market opportunities to capture value while reducing environmental impact.

Translating emissions-reduction goals into a practical reality involves working on three fronts at once: redefining the decarbonisation business case in finance, building an integrated sustainability production system into the organisation, and assembling an infrastructure to support tactical innovation in operations.

Increasingly, organisations looking to finance emissions-reduction initiatives can access the necessary capital at low cost. Governments and private investors are showing a greater willingness to offer long-term loans at favorable terms to fund such projects. Sustainability-linked bonds worth more than US$200 billion were issued in 2020, for example, pushing the total market for such securities above US$1 trillion for the first time. Some programmes even offer borrowing costs linked to the carbon-reduction impact of investments. In February 2021, drinks maker AB InBev agreed to a US$10.1 billion credit facility that links interest margins to several sustainability goals, including group-wide carbon-emissions reductions. Using such structures, companies can often secure funds for investment at less than half of their existing cost of capital. That is enough to shift the NPV of plenty of emissions-reduction projects from negative to positive.

In the context of the transition to net zero, companies can also

revisit their project-investment criteria. At many organisations, projects that improve

efficiency or reduce emissions must today pass the same financial tests as any

other capital investment. That usually

entails a maximum payback period of two years. Extending the maximum payback period to five

years, for example, allows organisations to take a longer-term perspective on investments

that could make a meaningful difference in their climate-change impact.

Alternatively, companies can explore new funding and ownership models for low-emission assets. Original-equipment manufacturers or third-party operating companies may be willing to retain ownership of equipment such as biomass boilers, for example, while the end user pays by unit of energy consumed. In Romania, for example, specialty chemicals company Clariant is building a 50,000- ton capacity plant to produce ethanol from agricultural residues. Steam and electricity for the facility will be provided by a dedicated biomass cogeneration plant installed and operated by German energy company GETEC.

Another option for companies is to introduce an internal form of carbon tax by including the cost of the carbon emissions explicitly as a line item on the profit and loss accounts of their plants and business units. The funds collected through this mechanism can then be ring-fenced for use in emission reduction projects. Dutch chemicals company Royal DSM, for example, introduced such as scheme in 2016, setting an internal carbon price of €50 per ton.

Many organisations have dozens of potential emission-reduction projects sitting on their shelves because their business cases failed to meet the requirements for investment, sometimes by narrow margins. The combination of cheaper, more accessible capital and a full life-cycle perspective can unlock multiple opportunities to simultaneously reduce emissions and improve financial performance.

Designing, running, and improving a low-carbon manufacturing network and supply chain is an intricate task. Organisations will need the skills, processes, and data to identify and implement efficiency improvements across their operations. Today, all three are in short supply.

The development of an end-to-end sustainability production system will require a systematic approach to the acquisition and development of capabilities across the workforce. Companies will also need appropriate supporting infrastructure across the wider organisation. That might include investments in new analytical tools to help staff interpret sustainability-related data, and changes to KPIs, targets, and incentives to promote continuous improvements in energy and resource efficiency.

Several companies are already pursuing this approach. A large-scale, ten-year operational energy-efficiency programme at one major chemicals player focused on capability building among frontline process engineers. Hundreds of staff across the organisation developed the skills to understand the root causes of losses and process inefficiencies, aided by new analytical tools that helped them identify and evaluate the impact of detailed process changes.

The programme has reduced carbon emissions by 10% while generating savings of about €100 million per year. That impact was achieved not through big investments in new equipment but through dozens of smaller measures scattered across the business. One site alone implemented more than 30 separate projects. Notably, the company made no special financial provisions for efficiency improvements; projects had to demonstrate a three-year payback like any other investment.

The road to net zero involves several distinct steps. Companies must understand their current carbon footprints, identify strategies to reduce and ultimately eliminate carbon emissions, and implement the necessary changes.

The drive to reduce Scope 3 emissions generated in the upstream and downstream value chain, meanwhile, will require companies to extend their sustainability production systems to include functions such as procurement, product development, supplier development, sales, and logistics. Measuring, monitoring, and improving Scope 3 emissions in the upstream supply chain will demand extensive changes to current approaches to supplier selection and management, for example, along with new analytical skills in the responsible teams. Companies will want a comprehensive carbon accounting-and-control system that runs alongside its financial equivalent. Such systems are in their infancy today, but development is accelerating. In mid-2020, chemicals company BASF began to publish full details of the carbon footprints of the 45,000 products in its portfolio.

The transition will also require effective cross functional coordination. Carmakers are already exploring opportunities to replace high-quality, high-footprint virgin aluminum with lower-grade, low-footprint recycled aluminum. That calls for collaboration between product development, sourcing, and manufacturing teams. The ability to demonstrate better environmental performance can boost sales too. Some materials companies are already using their sustainability credentials and long-term improvement plans as an argument for their products over rivals’.

The third critical element required to operationalise a company’s carbon-reduction strategy is tactical innovation. Many of the moves required to drive down overall emissions will involve the adoption of new technologies and approaches, the costs and benefits of which may be highly site-specific. Half of the carbon emitted in ammonia production is pure CO2, for example — and therefore could be ideal for carbon capture and storage (CCS). In Europe, ammonia plants located close to ports have opportunities to transport this gas in marine tankers for storage in depleted offshore oil and gas wells. Our calculations suggest that this approach was cash-flow-positive even at the February 2021 carbon price of €40 per ton.

Similarly, advanced heat recovery, zero-carbon electricity, hydrogen, biomass, and geothermal and nuclear heat are all potential substitutes for the fossil fuels used to produce process steam. The best choice for a given site will depend on the local price, societal acceptance and availability of each fuel type.

Companies will need the ability to pilot and scale up new and unproven technologies within their existing production networks. That will involve partnerships with start-ups or research organisations to pursue breakthrough innovations — and it will also require adequately funded and supported in-house capabilities. Government support for such initiatives is increasingly available. The EU Innovation Fund, for example, plans to invest €10 billion on low-carbon innovation over the next decade, with funding earmarked for small-scale projects alongside flagship innovation efforts. One candidate for such tactical innovation might be the development of high-temperature heat pumps to reduce energy consumption in the food industry’s sterilisation and cooking processes.

Capex-replacement cycles present another opportunity for site-level innovations and technology investments. A steelmaker facing a €500 million investment to replace a coke oven battery, for example, might consider a switch to more efficient alternative technologies, such as a jet-process basic oxygen furnace. It could also choose to invest in electric arc furnace technology, switching the feedstock to direct reduced iron produced using natural gas with CCS, or using hydrogen.

Once again, these are decisions that cannot be left to the boardroom alone. The best answers for any site will depend on specific factors, including its location, the availability of low-cost capital or government support, and the strength of the organisation’s long-term commitment to the technology or market segment.

Proven and emerging technologies and operating approaches, if applied

at scale, will be enough to take energy-intensive companies perhaps 40% of the

way along the emissions-abatement curve. The remainder of the journey will require big

bets and big steps into the unknown. As

they consider those choices, businesses will need to decide the strategic

posture they wish to adopt in the carbon transition. Some organisations will seek to play a leading

role, pioneering the adoption of sustainable technologies and business models. Others will adopt a “last man standing” strategy,

seeking to retain their existing approaches for as long as customers and

regulators permit. Between those

extremes, companies may choose to pursue fast-follower or slow-follower

strategies, holding off on major shifts until approaches have been proven

elsewhere (Exhibit 4).

Based on their strategic postures, companies will want to reevaluate their existing portfolios, potentially disposing of assets or exiting certain businesses. In other areas, they will likely need to place their big bets across one or more of three key dimensions: geographies, products, and processes.

— New geographies: Locating manufacturing facilities for less energy-intensive products closer to the point of end use can significantly reduce carbon emissions generated during transportation. For energy-intensive products, proximity to new feedstock sources or sources of low-carbon energy can be even more advantageous. Saudi Arabia, for example, has announced plans to build a new green hydrogen plant powered by 4 gigawatts of wind and solar energy. Much of the plant’s annual hydrogen output will be converted to 1.2 million tons of ammonia and exported worldwide as a low carbon energy source and chemical feedstock. Australia, which has abundant ore resources and significant renewable-energy potential, could become an advantageous location for the production of iron using green hydrogen, for example. The move up the value chain, shifting from an exporter of ore and coking coal to a producer of iron, would generate new value for the region. And, by halving the mass of exported materials, it would have a positive knock-on effect on transport emissions.

— New products: Organisations may choose to shift into lower-emissions product and market segments. Manufacturers of cement-based building components might migrate into engineered timber alternatives. Materials players could invest in novel chemical-based recycling technologies for plastics. Meat and dairy producers could enter new food categories derived from plants, cultured meat, or insect-based sources of protein. That shift is already underway, with major food companies making large investments in the sector. In 2016, dairy products maker Danone made its largest acquisition in a decade with its US$12.5 billion purchase of WhiteWave, owner of the Alpro brand of plant-based foods.

— New processes: In many industries, the known technologies required to deliver net-zero operations are value destroying, if they exist at all. To remain viable, therefore, companies will want to radically reinvent their processes. Heavy industrial sectors face a multiyear effort. Brazilian metals company Tecnored is developing a more energy-efficient process for production of pig iron that uses pellets of powdered ore combined with coal or biomass char as a reducing agent. It has been operating a development plant since 2011 and, having proved that its process is cost-competitive with conventional methods, is now working on a commercial unit with a planned annual capacity of 500,000 tons. In the production of ethylene, Dow and Shell have announced research into electrically powered steam-cracking technology. Elsewhere, laboratory-scale demonstrations have shown that replacing the conventional high-temperature steam-cracking process with chemical looping–oxidative dehydrogenation could reduce carbon emissions by almost 90%, cut operating costs, and debottleneck existing assets.

To succeed in these moves, organisations will want to move more R&D expenditure into sustainability related topics. They have room to do so. In 2020, global R&D expenditure on technologies to fight climate change was estimated at around US$80 billion. That is less than 5% of the world’s US$1.7 trillion R&D budget.

The transition to net-zero emissions will have a profound impact on almost every aspect of business. Success will require a transformational approach. For industries that have relied on the same fundamental technologies for a century or more, the degree of change required in the next three decades may seem formidable, but it is not without precedent. Neither the internet nor the mobile phone had achieved large-scale adoption at the beginning of the 1990s.

Such a transformation must begin with a decarbonisation vision, determining the role the organisation seeks to take through the carbon transition and beyond, and laying out the scale and scope of the operational changes and strategic big bets required to reach it.

Achieving that change at the necessary pace to meet global climate goals will still require companies to juggle thousands of initiatives and develop entirely new technologies, all in an environment of significant uncertainty. That will require careful planning, with development of new decarbonisation “playbooks” that help business prioritise and sequence their carbon-reduction actions. Whatever their strategy, companies must also adapt targets, performance metrics, and decision-making processes across the organisation to ensure that staff at every level are motivated and supported to achieve emissions goals.

Finally, to successfully operationalise their emissions reduction efforts, companies will need to develop new capabilities at a transformational scale. That capability-building effort needs to be broad, equipping the majority of staff with the skills they need to understand and act on sustainability related sustainability data. It also needs to be deep; developing a task force of process optimisation and sustainability specialists that can help site teams to drive rapid improvement, for example.

For any company with ambitions to remain viable beyond the middle of this century, the race to net zero emissions is already under way. Yet, the formidable technical and economic barriers they face has left many organisations stuck in the starting blocks, paralysed by the abatement curve.

Surmounting those barriers will require a transformation mindset

with two primary elements. Beyond the

boardroom, companies will need to operationalise at scale, capturing short-term

value creation opportunities by equipping their frontline staff with new

skills, new tools, new processes, and new infrastructure. Within the boardroom, meanwhile, leaders will

need to rethink their strategic positioning, adapt their existing portfolios, identify

the growth opportunities emerging from the disruption of decarbonisation, and

place big bets on their long-term futures.

No comments:

Post a Comment

Thank you for taking the time to share our thoughts. Once approved, your comments will be poster.